Looked long and hard at 20 to 30 ton presses. Even thought about making one using an inverted hydraulic jack. (plenty of how-to vids online)

Finally found one that didn't break the bank and yet had a lot of the features I was looking for.

It has a direct-reading tons/psi gauge, Movable cylinder left-to-right, and air-over hydraulic pump.

Granted, the air-over does not give much tonnage, but provides a quick way to move the ram down.

This is a nicely made press of surprisingly good quality for being made in China.

Model BD-PRESS-20A. It is distributed through Discount Ramps and I bought it on Amazon for about $500. (I see they're higher now)

I was happy with the price & the quick and free shipping that Amazon Prime offers, but it might pay to shop around.

The freight on this item alone would offset the yearly Prime membership cost.

Assembling the press took some time, but nothing overly complicated. Helps to have an A-frame hoist ! But, no fit-up problems at all.

So, some mods were in order right away. Casters (fixed in the rear, swivel in front) were bolted on after adding a small plate to the inside of the bottom rails. Surplus Center caster set p/n 1-4706

Next was to add a small winch (boat type) to raise/lower the "work press table" as this is a Royal PITA to manually move without it falling to the floor, or worse, on one's foot.

Even more so if you have parts or spacer blocks, aka heel blocks, on the table and need to move it up/down.

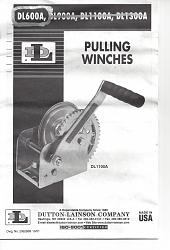

Modified a Dutton-Lainson winch by adding a 2" diameter "spool" to the drum, so that the cables start winding faster. The stock spool was only about 5/8" diameter.

The cables are then routed over some pulleys

and connected to the spacer tubes using some electrical ground wire clamps.

.....here, short chain links welded to the spacer tubes of the table provide an anchorage for the 1/8" cables

I didn't like the way the cylinder plate fit loosely on the top beams; made things wobbly and there was wasted motion when pumping; so I modified that arrangement to allow it to slide left/right, yet have very little clearance in the vertical plane.

Put a roll pin in the head of a 1/2-13 HexHd screw just to take up what little slack there was. 1 in front, 1 in rear.

Next, I visited the local Goodwill and got a nice alum cook pan. Made a swing-out frame and holder for all the press tools needed.

A friend had a long piece of a 4-sided V-die and we cut off an 8" long piece. Drilled holes in the ends and made a handle for it

(Like to keep my toes) Made a couple of V arbors for the ram. These sure come in handy for bending.

The swing-out pivots outward to the left and allows the table to be moved to the lowest setting without getting in the way.

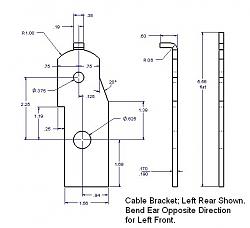

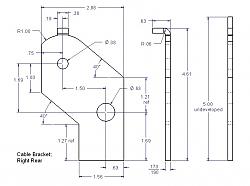

I've got some drawings of the pulley mounts if anyone is interested. Got the Dutton-Lainson p/n too.

gatz

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks