Bearing puller tool from bearing. By metal homemade. 5:36 video:

Bearing puller tool from bearing. By metal homemade. 5:36 video:

HomemadeTools.net founder (2012) and CEO

Join thousands of us, and start building your own tools today.

Frank S (Sep 2, 2023)

A lot of work, only to have it shatter the first time he uses it. The concept is valid though for a wide jaw puller. it might last a while longer if he were to cut a couple of crescent shapes and weld them to the back side of the bearing races. The heat from welding along the entire perimeter will serve to anneal some of the brittleness out of the race while the extra steel of the added stiffener will make it a more useful tool. but he has another problem that being, the all-thread rod if he didn't use B7 stud grade rod the threads will wear quickly, or the rod will bend.

Never try to tell me it can't be done

When I have to paint I use KBS products

Philip Davies (Sep 2, 2023)

I think that you are looking for non-existing problems, Frank. A puller like this is for occasional use at best. I have several special purpose pullers that i have made over the years and many have standard hardware store all-thread. I have never had any problems with wear. The puller in this case will either break or bend long before he has to worry about thread wear.

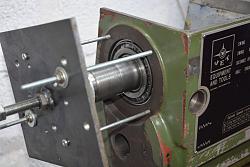

Here is an example of one of mine. The multiplicity of holes indicates that it is used for many different jobs, mainly crankcase disassembly and reassembly but in this case for pushing out a lathe spindle. Not all tools need to be of Rolls Royce quality as many of your own testify to. I agree that the puller in question leaves much to be desired and I would expect it to be next to useless.

nova_robotics (Sep 7, 2023)

Thanks tonyfoale! We've added your Lathe Spindle Puller to our Lathe Accessories category,

as well as to your builder page: tonyfoale's Homemade Tools. Your receipt:

[QUOTE=tonyfoale;228270]I think that you are looking for non-existing problems, Frank. I have several special purpose pullers that i have made over the years and many have standard hardware store all-thread. I have never had any problems with wear. The puller in this case will either break or bend long before he has to worry about thread wear. A puller like this is for occasional use at best I agree that the puller in question leaves much to be desired and I would expect it to be next to useless. /QUOTE]

I hear you Tony: Anytime I use hardware store threaded rod though I always figure the tool is very temporary at best or more probably going to be a one-time use tool, unless I over size it. I have a habit of abusing the things I make LOL

Never try to tell me it can't be done

When I have to paint I use KBS products

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks