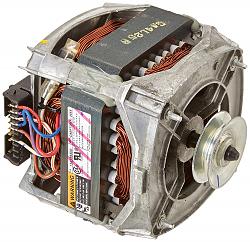

Just a comment for people running out to get free motors, every appliance motor (larger than a drill or wood router) I've seen here in the USA for a very long time has been a brushless motor of some type. Mostly simple induction motors with a run and maybe start capacitor. More recent ones may be 3 phase with a VFD controller like in my LG washing machine above. Here's a random example of a modern USA washing machine motor.

https://www.amazon.com/Frigidaire-13.../dp/B00M25OKO8

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks