3D-Printed 'DIGITAL' Angle Marker for Pipe

Website Link:

https://ctmprojectsblog.wordpress.co...rker-for-pipe/

For over 25 years I have used the CURV-O-MARK ‘Bubble’ Type Angle Pipe Markers … They work great; however, I wanted to be able to use a more accurate 'Digital' Angle Pipe Marker.

Sometimes I don't want to punch indentation marks in the pipe; instead, wish to create a group of accurate dots on the pipe with a Sharpie Marker to check my initial set-up ...

About a year ago I purchased an AccuRemote Digital Electronic Magnetic Angle Gage Level / Protractor / Bevel Gauge

Found it to be very accurate and decided to find a way to use it on pipe with a Sharpie & punch …

Had a project whereby I needed to mark out several areas on a pre-insulated pipe with a Sharpie Marker because didn't want to mess up the insulation with a punch during the set-up process.

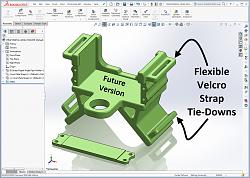

Designed a metal version out of Flat-bar Steel & Angle Iron but wasn't at home able to get out and weld it together, so designed a 3D-Printed version on my Laptop at the airport using SolidWorks CAD Software.

When I got home late at night, I pressed a button on the 3D-Printer before going to sleep and had the mount in the morning when woke up ~ Bonus 'Sleep-Working'

I'm still going to use my CURV-O-MARK ... but this 'Digital' version is an option when need better accuracy for unusual angles.

Updated Version with Flexible Velcro Strap Tie-Downs ... Although not sure I need the top straps because it is a nice tight fit-up.

... CHEERS!!!

For more photos click on this link for the full website post:

https://ctmprojectsblog.wordpress.co...rker-for-pipe/

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks