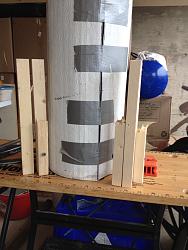

I've built myself a Gingery-like charcoal furnace. Here I present my infinitely adjustable spacers used to center my internal form. It's just 2 sticks of scrap screwed together with drywall screws and then separated with a chisel. Advance or retreat the screw to increase or decrease the space between the sticks. The short sticks attached to the sides of the spacers maintain the spacers' vertical position.

For my refractory I mixed 2:2:1.5:1.5 portland:finely sieved sand:clayerlite (all by weight). I mixed it tight, barely moist, and rammed it into place after which I set a 60 watt incadescent bulb for a long weekend while we went away.

I've also produced an infinitely adjustable airflow using a thrift-store hairdryer, a 1 1/2" steel pipe, and a piece of extruded Al tubing into which I made a cut which accepts the plastic support from a foam brush I used to shellac my flask. I cut a port to allow the blocked airflow an escape. Naturally, duct tape hold it all together.

For green sand I fine sieved some play sand achieving about a 50% yield. I mixed the sand with pounded and blendered clay at 11% clay by weight.

I can get the borax red, but I don't have a pyrometer. I'm melting cast Al, no cans or extruded. I'm guessing I get about 1300 *F no problem. So far no apparent damage to the furnace or major crack in the refractory.

Without question the art is in the pattern making. I'm brand new to this, now having 4 melts under my belt. My plan is to get to bronze eventually. That would mean a new furnace!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks