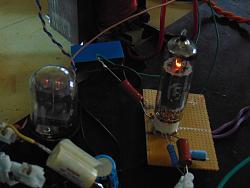

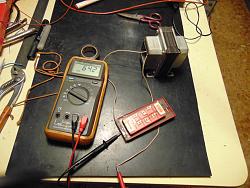

From what I saw in the previous post, I would doubt you are pulling 500W (.5A @1KV) from 2, 40W tubes...otherwise they would be melting the plates, grids, filaments and likely the glass...and you will Ruin your nice porcelain socket! IMHO you are pushing the tubes way tooooooo hard from the Pics above. Keep in mind that with the plates glowing deep red you are giving of pretty good amounts of infra Red and some X-Rays...Not good! One thing about tubes is the more you push them, they begin to break down and become LESS Efficient, with a much shorter life span. Properly breaking in a tube will give you the best results and last, usually longer than the life spec.

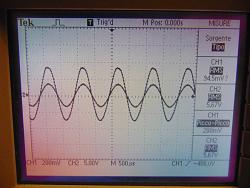

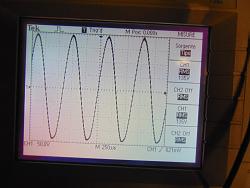

As for the 100mhz (if it is accurate) it may be some harmonic you are seeing because of the ~30mhz oscillator and it may have other spurious emissions you are picking up from the surroundings and the way the table is laid out...not sure I trust that digital meter at those frequencies.

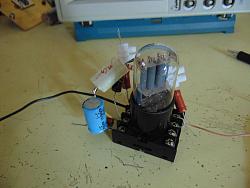

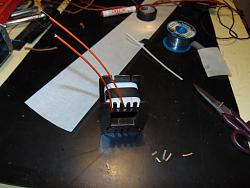

I can see RF burns on the coil ceramic. It will be metalized and throw off your the whole kit and Kaboodle of frequency/mH/resistance at these frequencies. Might try cleaning it with Acetone but be careful of your wire...it'll take the coating off in a heartbeat.

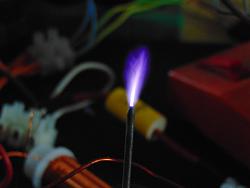

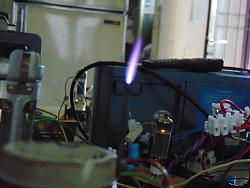

The flame definitely looks better shape and size.

Honestly Stefano I liked it much more when you were working towards the goal of an audio plasma speaker with a custom cone. This is starting to feel like a 5KW tesla music modulator, not an Audiophile Plasma Speaker. It is fun to push the envelope sometimes but it is dangerous...even with what you are working on and do Not want to see you hurt, nor discourage you from reaching your original goal!

Efficient, Efficient, Efficient, Efficient!Your Call!

Till Then,

~PJ

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

According to the "toilet paper" G2 on the Gu50 should be ~250V and you are pulling it to ground through the cathode.

According to the "toilet paper" G2 on the Gu50 should be ~250V and you are pulling it to ground through the cathode.

Bookmarks