There have been several posts here about tool demagnetisers, mostly using the mains in one form or another to get an alternating magnetic field. For many years I have used a modified transformer to both magnetise and demagnetise tools. It has worked well in each mode.

However, recently Mark Presling posted an ingenious demagnetiser which did not connect to any electrical supply, see here http://www.homemadetools.net/forum/d...ol-works-72881

Today was my wife's birthday celebration and it was a big family day with much eating and drinking, which kept me out of the workshop most of the time. I got free around 20:00 and I went for a quick fix. As I did not have much time I wanted something that I could start and finish in an hour or so and Mark's device came to mind.

It did not take long to turn up a piece of scrap aluminium and mill 4 recesses for the magnets. The other side of the block was turned down to 13 mm diam. to fit in a drill press chuck to spin it. This is shown following, with magnets glued in place. I made it with the magnets a little proud.

Click images for full size versions.

A quick test confirmed Mark's claims that it worked well. However, because the magnets were proud it gave a rough ride to any tool being demagnetised. I was also a little concerned that in general use the strong magnets would pluck ferrous swarf, nails, screws etc. from the surroundings, which would be hard to remove properly. To fix both I turned up a cover from some Delrin bar which I glued in place. The face part was just over 1 mm thick. I had tested that a 3 mm gap between magnets and tool was close enough to work well so I knew that 1 mm would give no problems with the increased reluctance. The cover was also a safety feature in that it prevents the magnets from being knocked out and becoming missiles.

The magnets can just be seen through the 1 mm Delrin cover.

As it turned out the wisdom of covering the magnets for cleaning reasons became apparent very quickly. Within seconds of fitting the cover I dropped the piece and it rolled under the lathe and came out like this

Cleaning that off was dead easy.

Here is the finished device shown working.

If I was making it with the benefit of hindsight I would have made it all out of Delrin and milled the magnet holes deeper but inserting the magnets from the rear. It would not work any better but would be a nicer solution.

-------------

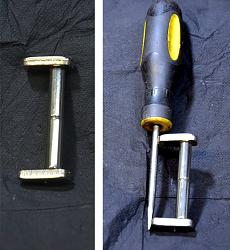

Sometimes it is helpful to magnetise tools such as screw drivers etc. to hold screws and other hardware in hard to reach places. I simply feed my transformer based demagnetiser DC in order to do that. In keeping with the idea of using a "no power required" device for demagnetising I wondered how easy it would be to make a magnetiser the same way. It turned out to be dead easy, it was also a no work device, I did not have to make anything. As the following shows I joined two longitudinally polarised magnets end to end and added a keeper to each end. Then I just put it on the tool, a screwdriver being the example, and that's all there is to it. Thank goodness for modern magnets, years ago, if you needed to magnetise something, you would have to stroke the object many times with a magnet to build a significant effect. This current method does not impart as much magnet effect as my transformer method but quick tests showed that it should be quite adequate for most if not all needs.

PS. Since I took the photos I cut out a 1 mm thick steel circle to use as a keeper for the demagnetiser which completely kills any tendency to collect ferrous swarf

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks