I find that I sometimes need to make knobs which can exert more torque than that of a hand gripped knob so I made a rotary broach to "drill" ¼" square holes in them to accept any ¼" square drive tool.

I made this rotary broach starting with an adjustable tool holder and then machined a bronze cup bearing and a steel tool carrier. The cap half of the tool holder has been machined so that its flange is 1º off of perpendicular and then installed pushed all the way to one end of its travel.

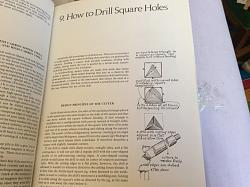

If a rod is inserted into its axis and the assembly rotated in a lathe chuck, the rod will appear to make an X shape as it rotates, and I make my broach bits so that they are the exact length as the crossover of the X and so don't trace a circle when rotated against a workpiece. Due to the geometry one corner point is closer to the work than the rest and it pushes the chisel point a small amount into each corner of the hole in succession removing a bit more metal as it does each time.

This broach bit is made from a lathe tool with the end dished out for rake using a Dremel with a cutting disc and mounted on center in my tool post, and then each flat side is ground with a slight relief angle.

The bit cuts much like a woodworking mortising bit except that the bulk drilling and corner chiseling are done in two separate operations. The thrust force is high so lots of lube is required but the corner cutting actually goes surprisingly fast and when I look down into the hole afterwards the waste appears like a four petal flower whose petals are turned inward instead of outward and they break out easily with a scriber. I've tested a square socket in aluminum and I can put as much torque on it as is possible with a ratchet handle of that size with no damage to the socket.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks