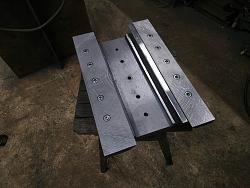

I bought a t-slot table for my milling machine. Table is from Polish Jarocin FWC25 milling machine. Dimension of the table are very simmilar to my drawings (20mm longer and 10mm wider)

Some photos before and after cleaning:

I also managed to finish Z axis guide. Cause of problem was last bolt on the bottom. Bolt was twisting end of the right dove tail. This is why it seemed to be wider. I drilled bigger hole and now everything is fine.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks