This project is a pretty much forgotten way to duplicating parts with a cutting torch or a plasma now that CNC has become the in word of the day.

Never the less I miss my old Victor DC2400 with its magnetic knurled stylus that would cut out any shape I could possibly conceive as long as I made my templets correctly.

My whole reason for building the tubing/pipe holder for my Craftsman lathe was to make this project.

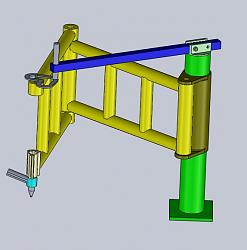

This is the cad rendering of what I am building.

Starting off with a plate laid on top of 1 of my handy work stands I began placing the pipes into position

One of the tools I frequently use for projects like this is my bander. I find that using a steel band to hold things together is 10 times faster than tacking a lot of scraps to a plate to make a jig if I am only making a one-off When fabricating multiples then a fit up fixture if the only way to go.

The steel banding also makes it easier to pull something square when you have half a dozen or so loose parts to contend with.

And we hardly ever think of the simple innocuous jack screw as a real homemade tool since we mostly just grab a nut and a bolt with a short length of pipe to force the final piece to where we need it

No matter how close parts are cut it always seams to me at least that one corner needs a bit of prodding to get it just right. in my 150 odd years of doing this kind of stuff (well 50 odd at least) I bet I have used a million of these simple little tools. I actually saw some for sale at a machinist supply once and my question was WHY?

First arm fabricated ready for clean up

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks