Originally Posted by

Paul Alciatore

Rick, you present some interesting techniques there, but it seems like a lot of trouble to avoid just throwing the parts in a mill-drill and using the handwheel scale (or DRO) to simply locate the two holes the same distance apart. No need to even scribe the locations, although I probably would just as a reality check.

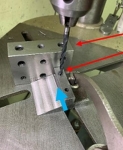

And as for the set screw trick, that would work but it would need to be replaced every time the bolt holding the two parts was loosened. Perhaps that will not ever happen, but there is an easier way to maintain alignment. Just drill a small hole through both of them while they are aligned and then install a spring pin. Two spring pins, one on each side of the bolt would maintain complete alignment. And drilling the two holes is a lot faster and easier than tapping the one. This is an age old technique that probably predates even the advent of the roll pins.

Oh, and the roll pins are a lot better way to align all of the assemblies. With them the holes and bolts holding the two pieces together can be done with more clearance so they would go faster. Pins for alignment and bolts to fasten them together. Each has it's own job.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks