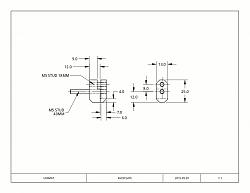

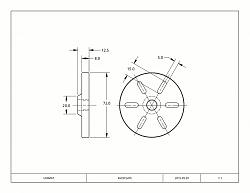

Here is a faceplate I made from scrap steel a few years ago.

It’s about 3” diameter and is threaded M12-1.0 so it can screw onto either the headstock or tailstock of an old Unimat, or anything else with the same thread.

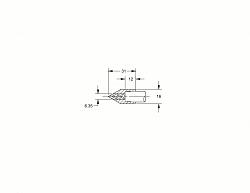

The clamps hold relatively thin work off the faceplate surface. They’re a little fiddly to use.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks