I have thought about building an out feed table for my 4x6 band saw. A few days ago I was cutting a chunk of steel and I did not catch it in time. The piece fell to the ground, catching the chip tray on the way, and I let loose a couple of swear words. The whole thing startled my wife, who came in expecting to see blood all over the place.

Time to build an out feed table.

I found a piece of 1.5 x 1.25 aluminum bar about 4.5 inches long, a piece of 5.5 x 6 x ľ aluminum plate and a piece of 2 x 2 x ľ aluminum angle.

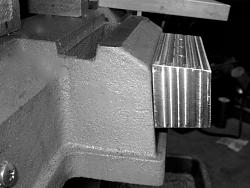

My saw has a small ground area on the out feed side of the blade. The first thing I did was to measure the angle between the ground surface and the unground casting.

Then I made a pair of angle bars to that angle, and cut the top surface of the 1.5 x 1.25 bar to match that angle. (See link below.)

I used the angle bars again when I drilled and tapped the holes for the table.

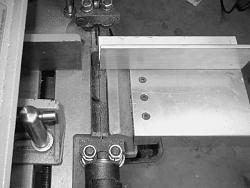

I used small slots to mount the angle iron (aluminum) to the new table so I could make any adjustments to align it with the fixed vise jaw.

To align everything up, I clamped a bar in the saw vice, then clamped the out feed table to the bar.

Once I was satisfied everything was in alignment, I used a transfer punch to carry the holes from my new base to the cast iron of the saw.

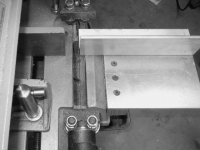

One thing I did not anticipate was to provide access to the set screw for the built in cut off gauge. I rarely use it, but I thought I should still drill an access hole. This is visible on the next picture.

The new out feed table precludes me using the factory stop block for anything less than 7 inches from the blade, but it will work if I need it for longer pieces. I am considering a stop block to fit on the fixed jaw extension, but most of my work is one off pieces, so I havenít done that yet.

With everything mounted and aligned, the final step was to cut the aluminum angle to length. This close fit seems fine now, but it may become an issue when I install a new blade or if the current blade gets knocked out of alignment. It would be an easy task to file it back a bit.

I hope this inspires some one.

Comments and questions are welcome.

Details about making the specialized angle blocks can be found here:

Specialized Angle Blocks

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks