I knew it was the weak link in my machine but it was working when all of a sudden

things were just out of wack. The cutter kept going deeper and deeper. Thought

the bit was slipping in the collet but that was not it. Finally noticed the maple mount

for the router was cracked. Actually it had separated. Now is the time to get out

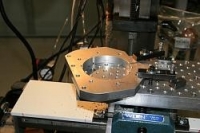

that faceplate for the mini lathe. The mill was only used with a mini pallet to put

the 4 grooves in the mount that provide clearance for the pins on the router.

Kinda forces you to fix something that knew you needed to update anyway.

When I built the CNC machine I did not have a lathe or a mill so now there

nothing to keep me from making one out of aluminum.

The pictures tell the story and after one day I have a proper mount for the

Porter Cable router. Cutting will start over tomorrow!

Cheers, JR

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks