G'Day,

I am in the slow process of restoring a Bridgeport 2J2 clone which has an align power feed fitted to the X axis.

The switch/es which interact with the table stops are missing... I basically have some wires coming out of the powerfeed ending with the pulverised remains of a double sided switch.

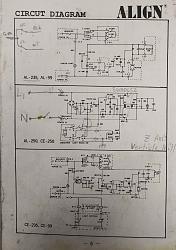

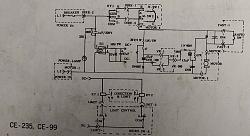

Does anyone have a wiring diagram for these type of power feeds, or know the configuration of the switch/es (normally open, normally closed, common return, etc?

thanks,

Des

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks