Originally Posted by

olderdan

I also detest those handles, designed by someone who never had to use one in the field like so many things these days. I once installed a shower enclosure for a customer which leaked in use, after several attempts to fix it I gave up and called the suppliers service engineer who on arrival said I told them they would have trouble marketing this but they would not listen to me saying it works fine in computer design

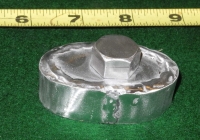

I have only encountered the plastic bodied variety but has the same handle, I would remove the central screw and handle and use an extended radiator key to work on the exposed square shaft. We all find our own ways to get through the days problems.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks