re Post *620......

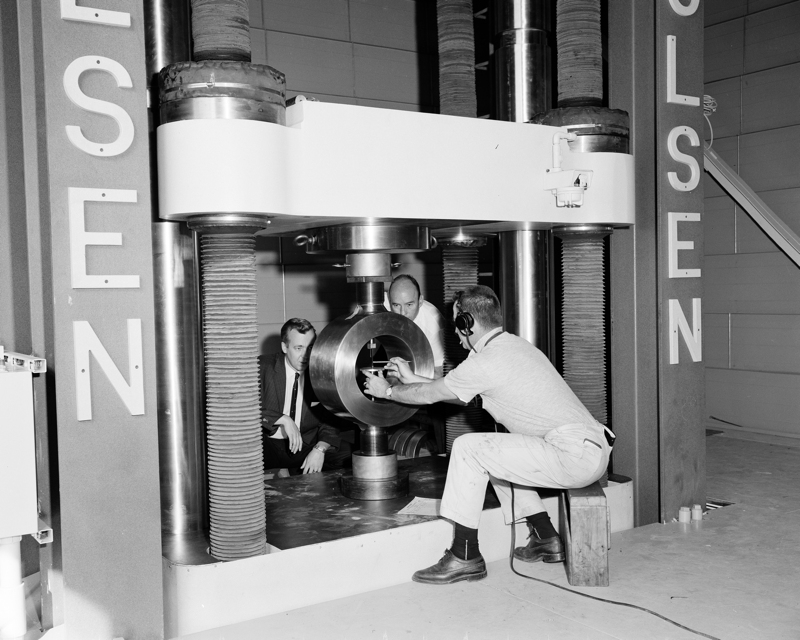

Interestingly configured machine, unlike any known to me, outside IIRC a 'Nicholson' rotary mill.(?). This somewhat more correctly a 'lathe' than a common VBL that traverses over centerline on gantry like ways. The quill carries spindle, suspended by counterweight, in a rise/ fall headstock. Normally the 'headstock' is rough positioning, quill for feed rate.

I don't see evident means of traverse, though yoke on right side suggests that axis, equaling a cross slide. The rest of it fairly conventional, clutch pedals, shift levers, pinion driven table etc.

Properly fixtured and clamped, this work of boring would be accomplished quickly.

With an eye on production, and sufficient capital, custom built machine tools were commissioned more often than realized. That very same specialization though makes seeing one a rarity.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks